Introduction

Coalmining has had a profound effect on Poynton. The village would look very different if there had been no coal in the area. In any study of mining in Poynton we must also look at the history of mining in Norbury, especially in the eighteenth and early nineteenth centuries, when there were very close links between Poynton and Norbury due to geological boundaries being different from township boundaries.

The geological setting

It is important to understand the geological situation in the area in order to see why mining developed in certain areas at certain times. Poynton is situated on the coal measures running down from north-east Manchester towards the North Staffordshire coalfield. A fault known as the Red Rock Fault runs north to south, approximately on the line of Towers Road, with a westerly downthrow of about 600 feet. To the east of this fault the coal measures of the Lancashire coalfield are absent and the lower and middle coal measures which were worked in this area crop out eastwards. West of this fault workable coal does not occur above 2000 feet in depth and consequently no mining took place in this area.1 East of the Fault the main seams to be worked are, in order of depth:

| Seam | Average Thickness | ||||

|---|---|---|---|---|---|

| Mill | 4'6" | ||||

| Poynton | ) | Sheepwash | 6'0" | ||

| 10 foot | ) | Cannel | 3'0" | ||

| Great | 6'0" | ||||

| Norbury 2 foot | 1'10" | ||||

| 4 foot | 3'10" | ||||

| 5 foot | 4'11" | ||||

| Poynton 2 foot | 2'0" | ||||

| Gees or Silver | 3'5" | ||||

| Reform or Waterloo | 2'6" | ||||

| New or Accommodation | 6'0" | ||||

| Arley or Redacre | 2'0" |

Coal seams in Poynton are also sometimes called "Mines".

|

General history of mining to 1831.

Early workings

Most of the coal seams worked in Poynton outcrop in the district and consequently some of them must have been worked from a very early date. The earliest record to be found is a lease dated 28 February 1589 which includes "Coal pit at Wourthe lately occupied by George Finche" 2 Twenty three years later we read of rentals received by Roger Downes of Shrigley for "the new Coalepitt and Coalemynes" in Worth 3 By this time the workings had probably developed beyond the stage of Bell Pits working the coal right at the outcrop and had become mines with workings away from the shaft bottom for twenty or thirty yards in all directions.

In April 1635 Edward Warren of Poynton made an agreement with William Downes and his mother Margaret which allowed him to use a "water channell or colesough in Worth lately used by Lawrence Downes late of Worth", for the processing (working) of coal found in Warren's land adjoining that of Downes at a royalty of £8 p.a. This agreement also mentions the coalpits of Edward Warren in Corley, which is close to the outcrop of the Cannel and Sheepwash seams north west of New House Farm. These pits were probably 40-60 feet deep. Both parties also agreed to fix the price of coal at 6d per quarter and not to undercut each other.4 Obviously water problems were already occurring even at the relatively shallow depths then being worked. In the 1640s a Thomas Mellor, husbandman, appears to have taken over all the coalworking in Worth. He rented the Worth mines in March 1641.5 All coal found was to be for the use of William Downes who was to provide a windlass, a rope, baskets and buckets as needed for the sinking operation, and when coal was discovered, new coal baskets, beside the windlass and rope which were to be kept in order by Mellor. Downes was to pay 8.25d per quarter for all coals "raised and layd upon the banke". One quarter of coal a week was allowed for candle light, sufficient timber for soughing, baskets, pickhelves and other necessities. He was also to sink shafts at his own cost - one at every 6 roods (33 yards) for raising coal, (it was cheaper to sink shallow shafts than to transport coal more than a few yards underground) and was to pay Mellor 4s per yard for sinking these shafts. In 1645 a Thomas Meton was also paying £12 14s 8d for working "Pointon Coale Pitts" 6

Norbury Hollow and the land around saw much mining activity around 1700 both on the Poynton and the Norbury side of the brook. There was much co-operation between the Warrens of Poynton and the Leghs of Lyme when it came to working the seams which were common to both as is shown by a Memorandum of 6 July 1707.7

"Whereas Peter Legh of Lyme in the County of Chester Esqe is about to sett a water wheele in Norbry For drawing water from a certain myne called the Great Myne, And whereas it may be of advantey to sett the ware (weir) close beloe A Pit of Edward Warren of Poynton Esqe called the Old Wheel Pitt & to turne the water into the sd pitt to gather A head in the old wrks on Poynton side. Now for the better encorayment of the sd Peeter Legh to goe on with the sd work, the sd Edward Warren doth hereby give liberty to sett his ware soe as to Demm his water into the said Pitt and tom the same in & out of the said Pitt. Paying to the said Edwrd Warren One Cart Quarte of coales yearly (if demanded) Dureing the tyme he shall make use of the sd works for pounding water as aforesd."

In Norbury in 1707-1708 there was one pit working and another being sunk. The profit for the year was £106 1s 8¼d on an output of 1069.25 quarters which was about 700 tons. To sink the new pit which reached a depth of 57 feet the cost was £95 17s 11d.8 Coal was selling for 4s per quarter (.67 tons) round coal, 3s per quarter small coal.

Edward Warren chose not to work his own mines, leasing them instead. In 1731 Matthew and George Priestnall paid £50 at Christmas and Midsummer for "Coalpitts and Miln".9 The Priestnalls were yeomen and no doubt combined coal mining business with farming. Up to the first decade of the eighteenth century coal working in the district had been on a small scale at relatively shallow depths. The major limiting factor was the lack of effective machinery to drain deeper workings below sough level, the only pumps being horse or water operated. Waterwheels were used as shown by several documents around 1707 but it is doubtful whether the Norbury Brook was either large or reliable enough to pump the large quantities of water that were found at depth.

The advent of the steam or more correctly atmospheric engine early in the eighteenth century, provided the technology to enable deeper, wetter pits to be worked. Atmospheric or 'Fire' Engines were introduced at mines all over the country at a surprisingly rapid rate and although Poynton and Norbury were not amongst the first to do so the new technology was soon adopted. A great change must have taken place in the area in the middle years of the century with deeper pits and larger outputs. Fire engines were expensive to install costing several hundreds of pounds at least and consequently could only be afforded by concerns of some substance. The first engine to be used in the area was at Norbury Engine Pit (SJ 939 855) although the exact date is not known. This engine was advertised for sale in 1764.10

|

|

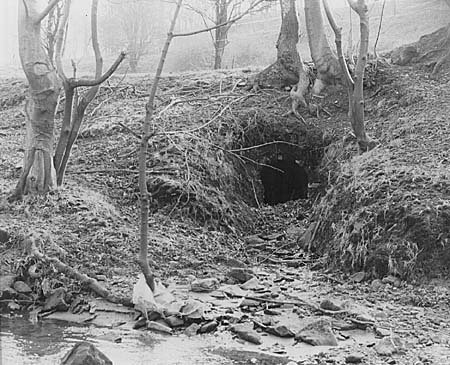

| The end of Sir George Warren's sough, (c1780) draining pits at Cawley Nursery, 1983. |

"To be SOLD, at Norbury Coal Work, near Stockport, in Cheshire A Fire Engine with all Materials thereto belonging, Cilinder twenty-eight Inches Diameter, and work in an eight Inch Bore, draws the Water eighty yards deep, and discharges one hundred and ninety five Hogsheads in an Hour. The Reason of its being parted with, is occasioned by sinking to a lower mine, and obliged to have a larger Engine. The above will be sold upon reasonable Terms, and ready to be removed May day next 1765. For further particulars Enquire of John Sergeant at Norbury aforesaid, who is Engineer to the same."

This pit was later known as Norbury Old Engine, House of Correction Engine or Sergeants' Old Engine Pit and was probably sunk to the four foot seam and being deepened to the five foot seam about 100-150 feet lower. When in 1765-66 a canal was proposed from the Weaver via Knutsford and Macclesfield to Stockport, great play was made of the fact that the new engine had been installed at considerable capital expense and that the collieries at Norbury, Poynton and Worth would be able to supply Macclesfield with much needed coal. It was estimated that the Norbury Pits alone could furnish at least 10,000 tons per year at 4d a cwt in Macclesfield.11 This was a far cry from the 700 tons of 1707-08. Other engines soon appeared in the district; Adlington 1768-69 and Poynton about 1780 (SJ 931 852) and another by 1793 (SJ 941 841).

It appears that in the 1780s Sir George Warren worked some of the pits himself rather than leasing out the workings. An old map12 shows a "Deep level by Sir George Warren 1780" running south from Cow Hey Wood Cottages for about 600 yards with workings to the outcrop of the Mill Mine, 220 yards east, a shallow seam about 4 feet thick which has also been worked in the banks of Norbury Brook. A little further east there were workings in the Cannel Mine with a sough running into the brook at SJ 946 855. In 1789 Sir George developed pits at the top of Poynton Park, probably Horsepasture SJ 941 841, Ash SJ 942 843, Tomlinson's SJ 943 843 and Wilson's SJ 943 843. Coal was carted across the park to a coal yard on the turnpike road where the council yard is now situated13. On 3 September 1791 Sir George set the scene for the comprehensive development of the mines by purchasing the Worth estate, which splits the coalfield, and the Worth coalmines and their machinery from Edward Downes for £24,000.

1793-1831 The Collieries leased

Soon after the purchase of Worth the name of Nathaniel Wright appears in connection with the collieries and he was to exert considerable influence on the collieries for over two decades. His name first occurs in a draft lease of 1793 14 between Sir George Warren, and Nathaniel Wright of Poynton, Gent and Matthew Pickford of Poynton, Waggoner. They were to lease the coal in the area of Barlows and Hilltop (Gees) Farms at a rent of £2000 per annum plus 1s for every 3s worth of coal raised over an unspecified amount for 21 years. It is not known if this lease was actually taken up but in December 1794 Wright states in a letter that he has "only one pit of Poynton Coal called Gees (next Rideker) which is wholly carried to the coalyards at Stockport and Maxfield" 15 and so it is quite likely that it or something similar was signed.

In 1794 Wright was attempting to lease the Norbury and Middlewood mines which it appears were in heed of considerable investment. He proposed that "by giveing me permission to Cart from the Bridge above Norbury Mill into How Lane (High Lane)......will enable me by saveing of Tole to deliver coal to Stockport cheaper than any undertaker of other the coals in Poynton, so far the sale being principally confined to myself at Gees and Norbury, I would for the priveledge and preferance in custom, undertake to lay this enormous sum out in so troublesome and doubtful an undertaking"16. At least £5000 was required to open out deep pits plus constant expenditure on machinery and drawing water for the Norbury workings and another £2000 for those in Middlewood.

An obstacle in the way of efficient working was the boundary between Poynton and Norbury along Norbury Brook which divided a large area of coal bounded by the Sheepwash fault in Norbury and the Great Fault which runs from Poynton Engine eastwards to Middlewood. In May or June of 1795 the problem was surmounted by the lease for 25 years of all the coal in Poynton to the North of the Great Fault by Sir George Warren to Thomas Peter Legh of Lyme 17 The rental was £400 per Cheshire Acre (= 2 acres 16 perches statute) for the 5 foot seam and £320 for the Silver (Gees) and 4 foot seams. Legh was to work the pits on the same level and in the same manner as his own and Sir George was able to appoint a man at his expense to descend into the pits to ascertain the quantity of coal worked and inspect their condition. It was also agreed that the coal from the 5 foot mine in the rest of Poynton, which was let to Messrs Clayton and Co for seven years, could be taken over the bridge in Norbury Hollow into High Lane. Sir George was to pay half the cost of maintaining the road through the hollow.

An interesting feature of the lease was that Sir George agreed to raise and sell only two pit quarters of coal in Poynton for every three quarters raised and sold by T.P. Legh in Norbury. If either should exceed their proportion they were to pay the other 2s 6d per quarter sold above the quota. Neither party was to raise or lower the price without the consent of the other.

This lease was followed by another dated 1 June 1795 between Thomas Peter Legh and Nathaniel Wright for the 4 Foot mine, 5 Foot mine and the Silver mine between the Sheepwash Fault and the Poynton Great Fault for 21 years, later increased to 28 years. The rent was 1s for every 4s worth of coal sold so long as it sold at or under 5s per quarter of 1500 lbs. Above 5s per quarter 33.3% of the advance was also to be paid as rental. Within two years of the start of the lease Wright was to erect a steam engine to the Silver Mine in Sergeants' Old Engine Pit "for laying dry and working the said mine with effect". Wright was also to employ Legh's tenants to cart the coal away unless he used his own carts or trams.

In fact Nathaniel Wright had anticipated the completion of the lease and had commenced sinking two pits of 104 yards depth on 30 March 1795 and by 19 May he was erecting two steam engines which he hoped to complete by Michaelmas. The extent of the works and size of investment is reflected in a letter of 7 July from Wright to Maire the agent of T.P. Legh.

"I have been going on with two engines and a paved coalpit road to the Turnpike the latter of which is completed, and I am now £1200 out of pocket; you must & well assured I don't want confidence in Col. Legh after doing this, yet life is very uncertain, and the circumstance of me laying out all my money in so precarious an undertaking (which will be nearer £4000 than £3000) seems to my friends reason sufficient to request your despatch in the business."

"It is certainly very much Col. Legh's and my interest to establish the Colliery as soon as possible, I can venture to say if the works continue to be carried on that at next Christmas the coals will be very productive to Col. Legh but to me as the adventurer, it is a matter of the greatest uncertainty, for since this treaty I must beg to mention to you that the Werneth Coal Company by virtue of the Canal propose to deliver into any part of Stockport a ton of coal for 8s 3d or 7s at the Wharf. Norbury Coal now sells in the Town for 11s 3d a ton and in the years 1792 and 1793 fetched 13s the ton."

"The water proves twice as much at Norbury as we had any reason to believe, in as much that I must have two Engines, besides the materials of the Old Engine proves good for very little indeed scarcely anything has been made use of ----"

The dangers of losing the Stockport market to canal-borne coal after so much had been invested in the works caused Wright to propose his own canal to Stockport. From a point close to Norbury Mill it was to ascend an inclined plane of about 500 yards in length at the top of which it was to divide with one arm going along Norbury Hollow to finally join the brook just above Norbury Old Engine. The other arm was to cross the top of Poynton Park and eventually follow the course of Poynton Brook through the Coppice to Coppice Bridge where it was intended to serve the Gees Pits and a new engine was to be installed. Wright intended to send 50 tons of coal per day at a transport cost estimated at 2d per ton per mile.

The line was surveyed and set out by Robert Fulton who was involved with the cutting of part of the Peak Forest Canal and an advocate of tub boat canals and inclined planes. Benjamin Outram viewed Fulton's line and made the estimates. In November 1795 after consultation with representatives of the Ashton-under-Lyne and Peak Forest Canals it was resolved to defer bringing in the Bill for the Canal and introduce it as part of an application for an extension of Peak Forest Canal to Macclesfield and Red Bull or Chesterton. This was the forerunner of the Macclesfield Canal and the scheme failed. The Stockport canal went with it and no more was heard about it. Possibly Nathaniel Wright was worried by the considerable extra financial strain the canal would have put on his already stretched resources or perhaps the threat to his markets from the other canal proved to be less potent than expected.

In the next few years Wright steadily established his workings, although it appears that not everything ran smoothly. A memorandum of December 1799 18 notes "Mr Wright to be answerable for his workmen as for damage done to the timber". He was also to erect an engine in Middlewood within one year. It also stated "If Mr Wright does not push the colliery in an active manner and work it with effect the bargain to cease and Mr Wright to forfeit whatever he has laid out----". Output slowly rose despite these problems. Rentals for Poynton and Worth Collieries rose from £2444 in 1795 with an estimated output of 26,000 - 28,500 tons to £4026 in 1803 for 43,000 - 47,000 tons but then fell back to £2965 for 31,800 - 34,800 in 1809 19.

By 1810 Nathaniel Wright was in a position to expand his interests and when

the lease for the rest of the Poynton Collieries became available he was able

to take over. The lease was dated 30 September 1810 between Nathaniel Wright

of Poynton and Lord and Lady Warren Bulkeley. He obtained the rights to work

coal, cannel, smut or slack in Poynton and Worth, south of the Great Marl Fault

for 21 years at a rental of 1s in each 4s worth of coal sold. All roads could

be used for carting coal from the pits except those across Poynton Park and

Worth Hall Meadow.

|

|

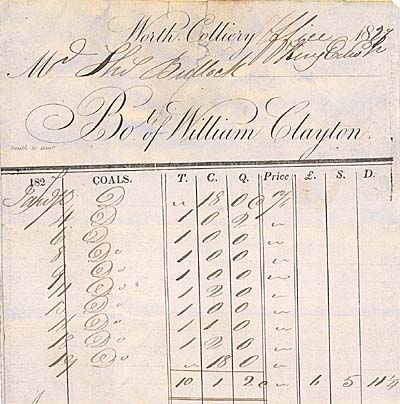

| Hilltop Cottage in 1983; winding engine house for Venture Pit, working c1820. |

In October 1811 Wright appears to have needed extra capital and an indenture for 28 October 20 divided the lease with William Clayton the younger of Worth who agreed to take a half share. This is probably the same Clayton of Clayton and Co who were leasing the 5 Foot mine in 1795. He also had collieries in Hurdsfield (Swanscoe) Haughton and Hyde. The agreement excepted "the two several mines called or known by the several names of the four foot mine and the five foot mine in Poynton aforesaid on the northerly side of the Great Marl Fault (which are now worked drained and laid dry by means of the two present engines in Poynton aforesaid called or known by the name of the Poynton Engine and the Speedwell Engine and in Norbury in the said County of Chester and adjoining to Poynton aforesaid and called by the name of the Norbury Old Engine which four foot mine the said Nathaniel Wright now works along with Norbury Colliery".

William Clayton also purchased a half share of the "several engines, utensils, implements, matters and things now belonging to the said collieries and coal works" for £818 which was one half of a valuation made by Mr William Sherratt. Clayton died on 23 October 1816 and left his share to his two grandsons William Clayton and David Shaw Clayton and his granddaughter Elizabeth Clayton. William appears to have soon taken over from the other two before 1826 and David Shaw Clayton later took up a lease on Norbury Colliery along with a Thomas Brooke. Nathaniel Wright, who was now a Gentleman of Brabins Hall, Low Marple died on 16 July 1818. His share in the collieries passed to his son John who was only 15 years old.

On 1 January 1826 John Wright withdrew from direct connection with the collieries when he sold his share of the lease to William Clayton for £2300 per year. Clayton also paid £6039 11s for Wright's share of the plant and equipment, this being one half of a valuation made by Thomas Sherratt of Manchester, Iron Founder. The inventory made at this time gives a clear picture of the concern.21 There were 18 pits; all had winding or pumping engines except Lane Side which was worked with a horse gin. There were also Gins at Worth Engine Pit (6ft diameter) Higher Smithfield (12ft), Gees New (11ft) and Horse Pastures. Gees Deep and Waterloo also had a Turn or Windlass. Most pits had a smithy and carpenter's shop and there were eight coke ovens at Accommodation. The headquarters of the establishment was Worth Office in the Hockley area and there was also a coal yard at Macclesfield. Several cottages were attached to the colliery including those at Petre Bank and three at Smith Field.

It

is interesting to note that the collieries were using modern techniques in that

all winding shafts except Lane Side were fitted with wrought iron conductors

and all pits had rail roads underground and used tubs for moving coal to the

pit bottom. Output increased dramatically during the period of the lease from

a vend of 28,219 tons in 1810 to 86,514 tons in 1831 and no doubt handsome profits

were made by the lessees. Poynton Collieries had developed into a large and

thriving concern employing several hundred people.

It

is interesting to note that the collieries were using modern techniques in that

all winding shafts except Lane Side were fitted with wrought iron conductors

and all pits had rail roads underground and used tubs for moving coal to the

pit bottom. Output increased dramatically during the period of the lease from

a vend of 28,219 tons in 1810 to 86,514 tons in 1831 and no doubt handsome profits

were made by the lessees. Poynton Collieries had developed into a large and

thriving concern employing several hundred people.

In 1824 300 workmen had celebrated the 21st birthday of John Wright when they assembled at Worth Office with Poynton Band and marched to the Crescent Inn for a dinner.22 Not everyone had been happy with the collieries though and in 1822 someone cut a winding rope at one of the pits although luckily this was discovered before anyone attempted to descend the pit.23

It is quite likely that William Clayton expected to obtain a new lease in 1832 but the estate had passed to George John Venables Vernon, 4th Lord Vernon, through his wife Frances Maria in February 1826 on the death of Elizabeth Warren Bulkeley. With the opening of the Macclesfield Canal in 1831, new and larger markets were available to the collieries and Lord Vernon decided that it would be more profitable to work the collieries himself through his agent William Henry Fisher and so commenced a period of 89 years of overall management by the Vernon family.

References to this section will be found

at the end of Poynton Collieries: 1832-57 Development under the Vernons

For further information see:

Poynton A Coalmining Village; social history, transport and industry 1700 - 1939, by W.H.Shercliff, D.A.Kitching and J.M.Ryan, published by W.H.Shercliff, 1983. ISBN 0 9508761 0 0

Chapter 3. Textile Work

Poynton Collieries: 1832-57 Development under the Vernons

Last updated 2.11.03