The Buckley Area

At one time there were 25 brickworks in and around Buckley in

Flintshire, North Wales. Most of them stretched in an arc

through the north end of the town and all were served, or

connected by tramway, to the Buckley Railway. This

provided a vital transport link, in particular to Connah's Quay

and its port. This export trade led to the introduction of

a unique form of transport - the shipping box. This was a

narrow gauge vehicle with small wheels built to carry

bricks. The wagons were run onto special standard gauge

vehicles at the nearest railhead or private siding and on

arriving at Connah's Quay were unloaded from the transporter

wagon and placed directly into the holds of waiting ships.

Subsequently the empty shipping boxes were returned from the

customer and the cycle started again. The Buckley Society

is an active industrial history group specialising in the

history of the Buckley brickworks.

Ashton, Buckley

Made at Knowle Lane brickworks. One of Buckley's earlier brickworks, having been established in the 1790's. Richard Ashton operated Knowl Lane Brickworks off Church Road Buckley between March 1841 and his death in March 1867. The site is now a housing estate. If you look on Google Earth 'Coniston Drive' CH7 3LA in Buckley is roughly where the brickworks stood. Upon the owners death Ashton's was leased by his widow to two brothers Frederick and Richard Prince who continued production there still trading under the company name. Presumably their products would have carried the Ashton's stamp after his death. Frederick had been a Manager at the works for Richard Ashton, it ceased trading in 1902.

Found by Mark Irwin in Glasdrummond/Mullaglass, a very small townland outside Newry in Northern Ireland

Buckley Brick & Tile: Brookhill brickworks/Gibsons/Gibsonite

Buckley Brick & Tile Co. Ltd was active from 1865 to 1963

FW is Flintshire White

The Metalline brand was registered in 1885. Photo by Chris Graham.

Photo by Martin Webster.

Photographed on the seashore at Crosby, Merseyside.

Found near Wrexham, B.H.B is Brook Hill Blue.

Photo by Thomas Hayman.

Gibsonite block, courtesy of the Buckley Society.

Photo by courtesy of the Buckley Society.

Photo by Richard Symonds.

Photographed in Corris, Powys.

Photographed in Corris, Powys.

Photographed at Corris by Martyn Fretwell.

Discovered on Baltray beach near Drogheda by Niall Kierans. Possibly from a shipwreck. Gibson's made engineering bricks from a particularly acid and heat proof clay and this could be an example of one.

Front and back of a Gibsonite paving brick. This one has a unique purpose. When the Queen Victoria Jubilee Bridge at Queensferry, Flintshire was built in 1897 the timber roadway quickly wore away and Gibson's brickworks at Brookhill, Buckley were contracted to supply a suitable hard wearing brick to resurface it. The brick is of extremely hard blue clay with pieces of what looks like hard wood pegs fitted firmly in the slots presumably for grip for horse transport. The underside has holes either for water to drain through or maybe so that there was an escape for air when they hammered the timber pegs tightly into the recesses. The wooden bridge was demolished in 1926 and replaced by the well known 'blue bridge'. Part of the collection of Bernard Trickett, photo and info by the Buckley Society.

Buckley Junction Brickworks, Jacobean brand

A late starter by Buckley standards, the works were established by John Jones and Henry Lamb in 1911 when they took on a lease of the site and set about working the clay. In 1919 Frederick Phelp Jones acquired the business and renamed it the Buckley Junction Metallic Brick Co Ltd. The company used the trade marks 'Jacobean' and 'City' for some of their facing brick products. In 1956 after the company became bankrupt the works were acquired by the Castle Firebrick Co, but this only lasted for three years before complete closure. Photos by Frank Lawson and information by David Kitching.

BCM means British Commercial Monomarks, a company formed in 1925 to provide manufacturers with a London address and mail forwarding service. Photo by Dave McNicholas.

Photo by David Kitching.

Photo by Jason Stott.

Photo by Alan Murray-Rust.

This modern version of the Jacobean brick was probably made at Lane End Brickworks on 1990. Photo by Ian Suddaby.

Castle Firebrick Company

Photo by Ken Perkins.

Found by Stephen Payton near the site of Connahs Quay railway station

Photo by David Kitching.

Photo by Helen Herbert.

Photo by Mark Baigent.

The original Castle Brickworks was established by William Malcolmson and George Alletson in 1866 with the Castle Firebrick and Coal Company being formed in 1875. In August 1925 the company put an additional new works into production at the former Elm Colliery site. This works concentrated exclusively on the production of building bricks and finally closed in August 1970 as investment in new plant was necessary and demand for bricks had been declining for some years. In its later years it was owned by John Summers & Sons.

Photo by courtesy of the Buckley Society.

Catherall

Jonathan Catherall (1689-1761) played an important part in the development of the industry. Catherall and Company survived in Buckley until the late 19th century, moving increasingly into brick and tile manufacture. Photo by David Kitching.

Photo by Frank Lawson.

Found on a roof at Edern near Nefyn, Gwynedd by Terry Hughes.

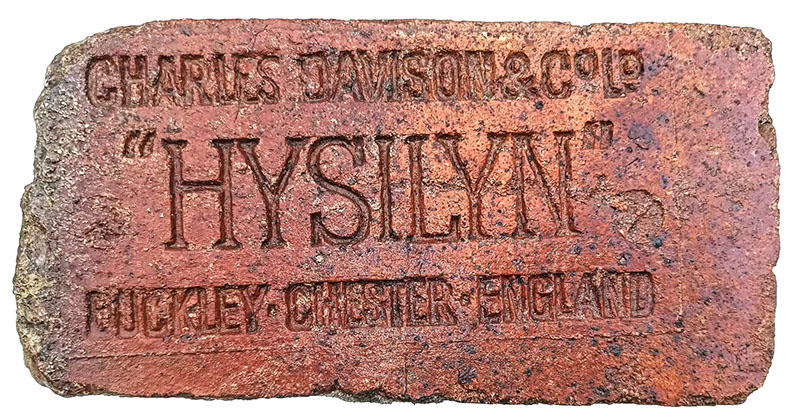

Charles Davison & Co.

Photo by Chris Tilney.

August 2011: A fisherman in Batticaloa, on the east coast of Sri Lanka, has just reported dredging an Adamantine brick up in his nets! June 2012: More Adamantine bricks found off Sri Lanka. There is a copy of an old Davisons catalogue here.

Photo by Jason Stott.

Photographed at Four Oaks Reclamation Yard nr. Sutton Coldfield by

Martyn Fretwell.

Photo by Danny Rylands.

Photo by Louis Delgado Gonzalez.

Photographed at Corris by Martyn Fretwell.

Ridge tile found on a pre-Civil War mansion in Louisiana, USA. This is the earliest Davison product I have seen and is notable for being stamped Hawarden. Photos by Julie Torres.

Photos by Frank Lawson.

.jpg)

Davison's specialised in refractory and acid resistant bricks. Charles Davison's Ewloe Barn Brick and Tile Works and Old Ewloe works was bought in 1844 and was eventually merged with General Refractories Ltd, and then taken over by the firm of G. R. Stein Ltd. The site closed in 1979.

Photo by Chris Tilney.

Found by Frank Lawson on the banks of the River Humber close to theCapper Pass works at North Ferriby

A 'Hysilin' brick stamp on display in Buckley Museum.

Photos by courtesy of the Richard Symonds collection.

A 'Rotary' block made at Davison's for use in cement kilns. It is

slightly curved in shape to line the kiln. Photo by courtesy

of the Buckley Society.

Photos by courtesy of the Buckley Society. Paul Davies of

the society writes: Obsidianite bricks got their name, I am

told by Ron Millward the 96 year old former Office Manager at

Davison's, from Obsidian which is a term for molten lava which has

set solid and would withstand exposure to most acids. It

didn't like exposure to fluorine gas though. Ron tells

me they were used a lot by cement manufacturers to line the tops

of chimneys where acid formed and eroded traditional bricks. When

I was cleaning the moss etc. from it I used a wire brush briefly

and sparks were flying from it!

Wikipedia definition - Obsidian is a naturally occurring volcanic

glass formed as an extrusive igneous rock. It is produced when

felsic lava extruded from a volcano cools rapidly with minimum

crystal growth.

Photo by Iain Taylor.

Found during excations of an old industrial area in Glasgow. Possibly they have been used on a site occupied by the Clyde Portland Cement Company. Photos and info from Mark Cranston.

Photo by Martyn Fretwell.

Photos by Chris Tilney.

Photo by Frank Lawson.

Photo by Ian Suddaby.

Drury

In the early 1860's Sandycroft Colliery & Brickworks worked

the site. It then passed through many hands until

ownership by the Shone family, finally closing in the 1960's.

Photographed at Corris by Martyn Fretwell.

Etna

The company of George Watkinson and Sons owned brickworks and collieries in Buckley in the 19th and 20th centuries, including the Etna brickworks.

Gibsons: see under Buckley Brick & Tile entry

Globe

The Globe firebrick Works opened in 1878 and it ended its life as a pottery works, closing in 1912. The wooded area of flooded clayhole is now one of Buckley's only remaining links to its brickmaking past.

Photo by David Kitching.

Hancock's Lane End Brickworks

The last brickworks in Buckley was at Lane End: it had been established in 1792 by John Rigby and William Hancock. In 1956 it became the property of the Castle Firebrick Company who also took over several of the other brickworks. Butterley took it over in 1971 and at its closure, announced in February 2003, it was owned by Hanson's. It had been one of the biggest and earliest in the area, and the last one to close in Buckley. The last chimney in Buckley was demolished at Lane End Brickworks on the morning of Friday 26th November 2004. It marked the end of a 250-year era for the town.

Although the location of the works stayed the same there was more prestige in using the name of the nearby town of Hawarden. This was because of its connections with the Gladstone family.

Photo by Phil Burgoyne.

This one is a paver.

Again a Buckley brick but this time pretending to be from Chester! Photos by David Kitching.

This was one of a number of special ones made over the years and commemorates the Queen's Silver Jubilee.

Photo by David Bell.

Photographed at Parc Glynllifon, Gwynedd.

H G A = High Grade Alumina bricks originally manufactured from the late 1930's at Hancock's Lane End Works. Later made at Catherall's Trap Works after Castle Brick had purchased purchased Hancock's in 1956, having already owned Catherall's since 1936.

Photographed at Coalport China museum near Ironbridge by Michael

Shaw.

Photo by David Kitching.

Parry's Ewloe Wood Brickworks

Photos by David Kitching.

One of the town's most important brickworks, operating from 1860 until the late 1960's. Their most famous products were dark blue paving bricks. Castle Firebrick Co. acquired the works in 1944 and turned production over to refractory bricks for cement kilns.

South Buckley Colliery & Brickworks

Photos by Ray Martin.

Photos by Chris Tilney.

North & South Buckley Colliery, Brick & Tile Co Ltd.

One of Buckley's largest works, it began life as a colliery. Amalgamation with a nearby brickworks saw its name change to the North & South Buckley Colliery, Brick & Tile Co. They were responsible for the production of the famous Rock brand. Closure came in 1914.

Photos by David Kitching.

Photo by Mark Howard.

Photos by Jason Stott.

Standard Brickworks

Photos by David Kitching.

Photo by Sam Burrows.

Originally opened by John Bates Gregory and associated with his nearby Mount Pleasant Colliery. It became the Standard Buff & Glazed Brick Co. specialising in hard cream coloured facing bricks. It ended its life making ceramic pipes and closed in 1969. Lower two photos by David O'Byrne.

The Catalogue of the Standard Brick Company, Buckley, c. 1900.