This is possibly a product of Edward Gibbons' Chilton brickworks. Photo by Stephen Limmer.

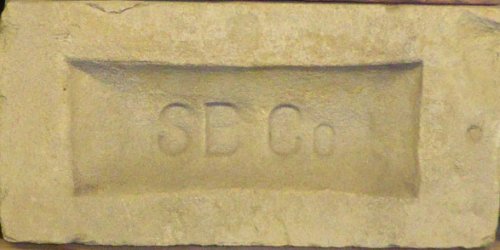

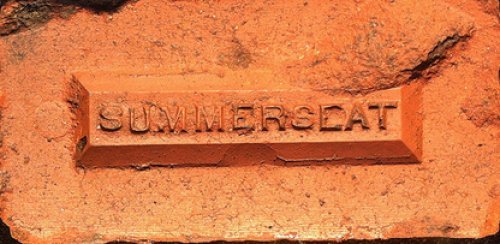

Summer Lane Brickworks, Barnsley Ltd., Summer Lane, Barnsley, South Yorks. The business was wound up in 1913. Photo & info by Frank Lawson.

Photos by courtesy of the Frank Lawson collection. The Summit works was near Littleborough in Lancashire.

Photos by courtesy of Colin Driver.

This was made at the Ifield Brickworks in 1880, the image is in black and white, thanks to Richard Symonds.

The Sun Brickworks at Old Linthorpe, Middlesbrough was run by William Stubbs before transfer to another proprietor in 1876. The business was offering common and pressed bricks, flooring squares, and ornamental bricks of all kinds. Thanks to Mark Cranston for information. Photo by Chris Tilney.

Photos by Chris Tilney.

Photo by Phil Sidwell.

Photo by Richard Paterson.

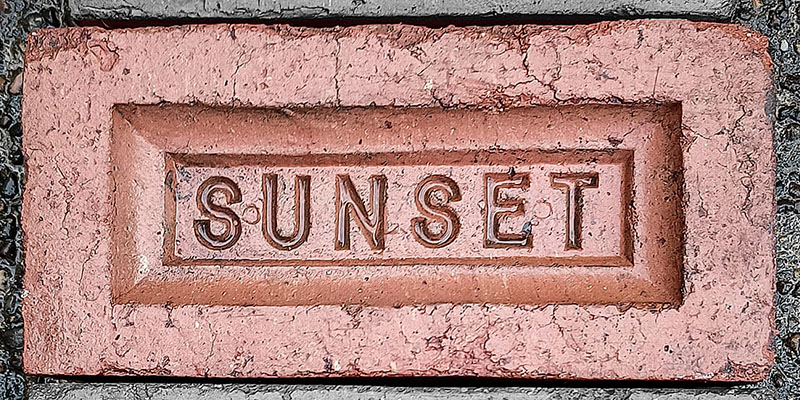

Photographed at Beamish Museum. Sunset Brick & Tile Co., Cowgate, Newcastle upon Tyne. Founded 1921 by W Cochrane-Carr. Shale was extracted from a nearby quarry using explosives until 1953, when a mechanical excavator and drag line were introduced. By 1967 the neighbouring quarry was exhausted of shale and, with no nearby economic supply, the works closed. Info and photos by courtesy of Frank Lawson.

Photo by Anthony E Gray.

Photo by Phil Burgoyne.

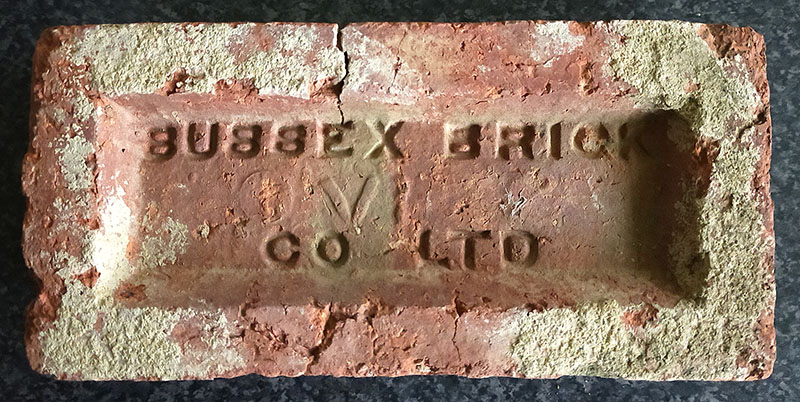

Sussex Brick Co Ltd. Works, Warnham; Southwater, Horsham; Pennybridge, Tidebrook, Wadhurst; Lingfield; Wadhurst & Tonbridge. Kelly's Directory 1930. Photo by Frank Lawson.

Photo by Laura Barr.

Photos by Frank Lawson.

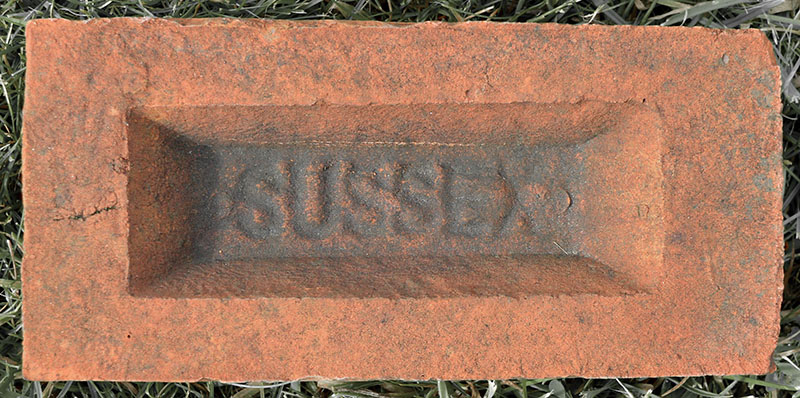

Photos by Martyn Fretwell. Sussex Hand Made Brick Company at Hastings, has produced hand made bricks since 1896 and still uses the Wadhurst Clay found at the rear of their works.

Photo by Phil Burgoyne.

Photo by Dave Askew.

Photo by Frank Lawson.

Photo by Darren via John Harrison.

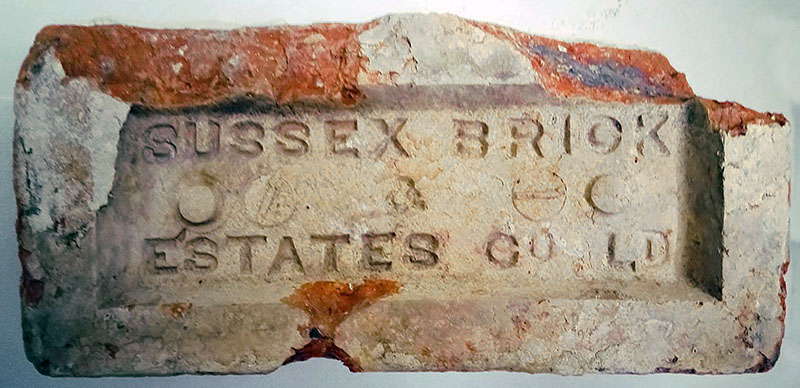

Richard Symonds came across this near Southwater in West Sussex and has done some research on the history.

'Peter Peters, of the firm of Horsham Builders which was responsible for the initial development of the Keymer Brick & Tile Co, sold out in 1899 and the new owner, a London builder, formed a company, The Sussex Brick Co. Ltd (not to be confused with the Hastings firm of the same name). and installed a new plant and buildings, intending to exploit the lower measures of the Weald Clay to make pressed bricks using the 'stiff plastic' process. two new coal-fired continuous kilns of the Hoffmann type were built, the coal being brought in by rail from Nottingham. Behind the kilns was a line of presses, fed with clay from a parallel line of grinding mills. The clay, at this stage, was still dug manually and delivered to the grinders in trolleys, propelled by an overhead continuous chain drive. However, the company soon ran into trouble. Initial problems, which led to uneven output and rising costs, were compounded by the recession in the industry, and in 1903 a new manager was appointed, fresh capital was injected and the Sussex Brick & Estates Co Ltd formed.

The new company bought a third continuous kiln into use and increased the output of pressed bricks to 12 million annually. In addition, 8 million bricks a year were being turned out by the two seasonal yards which were still in operation, using the top six feet of clay which was unsuitable for the production of pressed bricks. All this was running counter to the general trend in the county, which was one of decline, and may have been attributable, in part, to the company's superior marketing technique as well as some imaginative use of public relations to advertise is wares. In 1912 a steam excavator was brought into use in the claypit at Warnham and was made the occasion for celebrations, which were reported in the Sussex Daily News on 8th Feb.: '... a leading Sussex industry is that of brickmaking, for on large and small scales, it is to be met with wherever one cares to travel. At Warnham, modern methods can be seen at work to the fullest extent. There the Sussex Brick and Estates Company Ltd., who have also another works at Southwater, show the latest thing in brickmaking, for speed of output, combined, of course, with quality....'.

The above data was extracted from the publication 'Brickmaking in Sussex' ISBN 1 873 793 197 (1993), by M. Beswick.

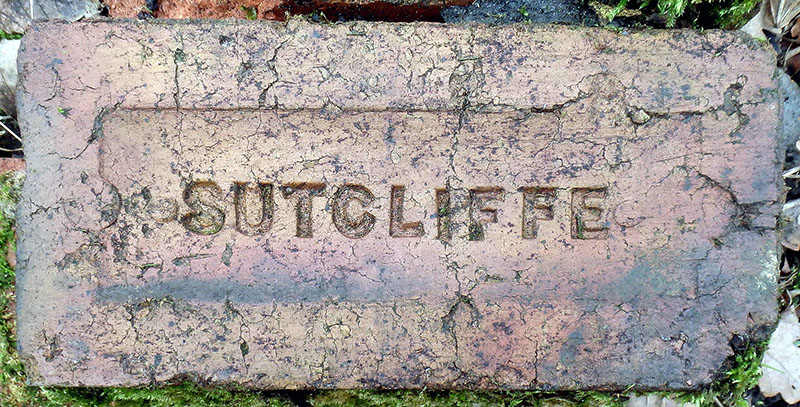

Thomas Sutcliffe, Wrose Brow, Windhill, Shipley, West Yorks - Post Office Bradford Trades Directory, 1887 & White's Directory of Leeds & The Clothing District, 1894. The works continued under Sutcliffe management until at least 1912. Info and image by Frank Lawson.

Photo by Derek Barker.

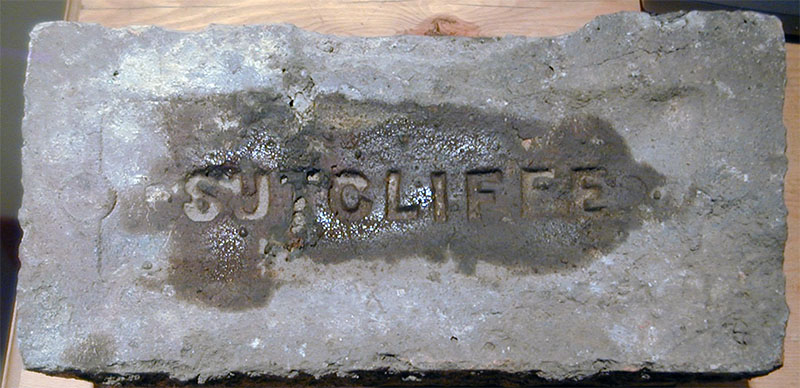

William Sutcliffe operated Armley brick Works, Stanningley Road, Armley, Leeds and Woodhouse Hill Brickworks. Listed between 1875 and 1912. Info by PRBCO and image by Frank Lawson.

Photo by Phil Burgoyne.

Photo by Chris Shaw.

It is not known from which brickworks in the Swadlincote area this brick comes. Photo by Martyn Fretwell.

William Swain, Howarth Cross, Halifax Road, Smallbridge, Rochdale. Photos by David Kitching.

Photos by Frank Lawson.

Photo by Ken Wyatt.

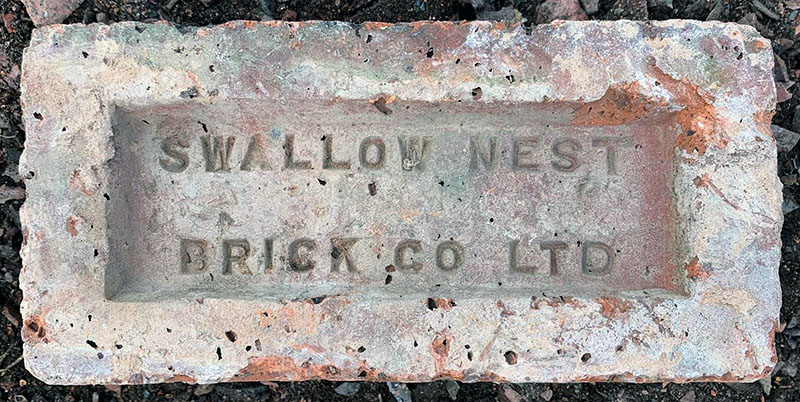

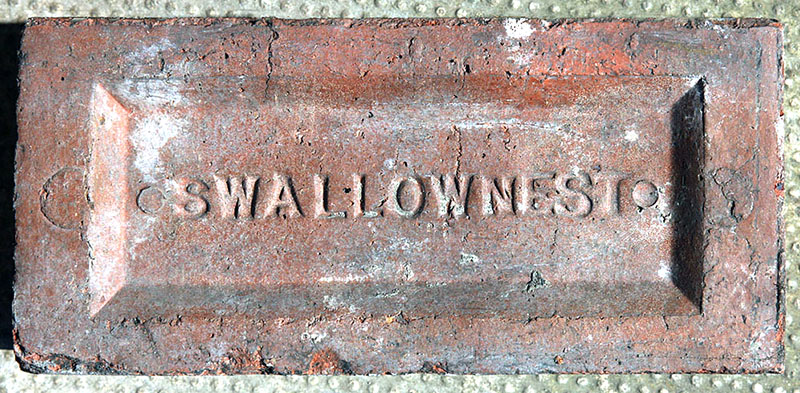

The Swalllownest Brick Co was situated at Swallownest to the east of Sheffield. Photo by David Kitching.

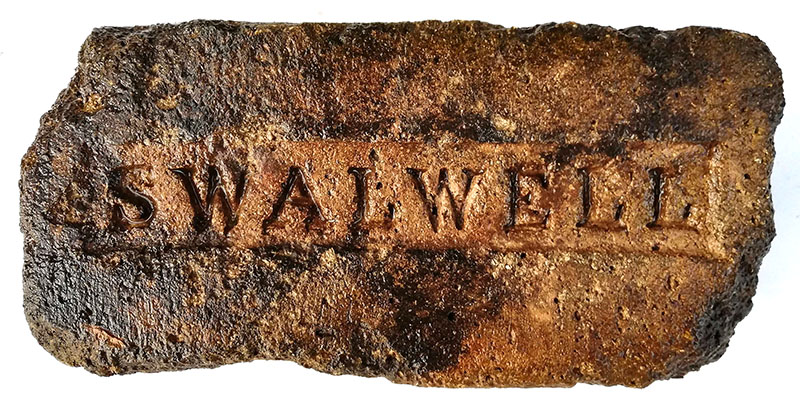

This is likely to be a product of James Snowball's Swalwell works at Derwenthaugh, Gateshead. Photo by Chris Tilney.

This one is believed to be from the Middlesbrough brickworks of Alderman Charles Swan who had a works there in 1887. Photo by Frank Lawson.

Photo by Jason Stott.

Photo by David Fox.

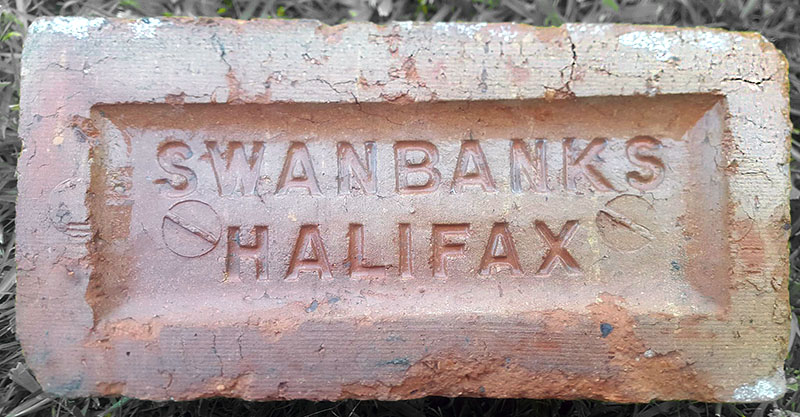

In 1864 the Swan Banks Coal and Brick Company was formed in Halifax, West Yorkshire. By 1873 the company made an agreement to take 24 acres of both hard bed and soft bed coal under Marsh Farm but by 1875 the mine had closed. The Swans Bank Brick and Coal Company continued to make bricks at Bailey Hall Road, where they quarried shale. The Rawson Family owned the coalmine from the 1820s and developed the site between the Halifax canal and the upland Marsh area of Southowram. The Halifax Brick Co was an association formed by: Morton's of Siddal, Swan Bank, Oates & Green, and Charlestown Bricks in the late 19th century. Photo and information by Derek Barker.

Photos by Frank Lawson.

Found by Roger Grimshaw in Hebden Bridge.

Photo by Chris Shaw.

Swan Brothers & Bourne, West Cliffe Brickworks, Burton Road,

Lincoln are listed in these trade directories, Kelly's 1876,

White's1882, Kelly's 1885 & 1889 editions. This works was

amalgamated into the Lincoln Brick Co. in 1889. Photo & Info by

Martyn Fretwell.

Photo by Chris Graham.

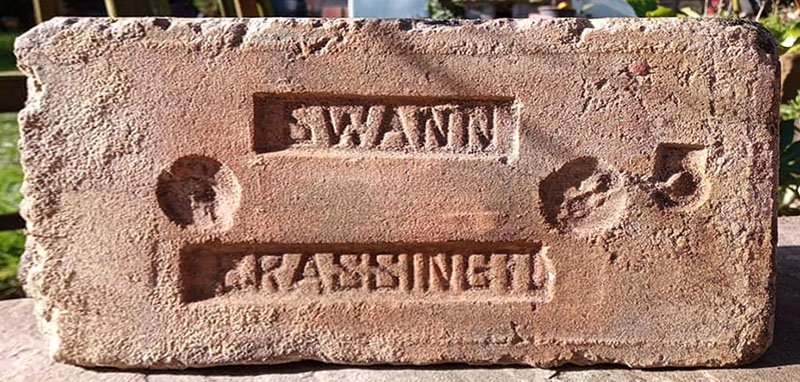

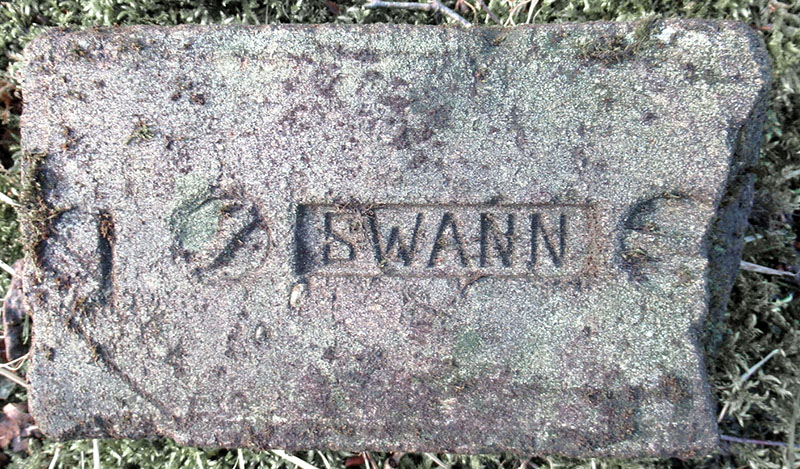

Swann Ratcliffe & Co. are listed at Brassington, Wirksworth

Derbys. in the Fire Brick Manufacturers section of these Kelly's

directories, 1912, 25, 32, & 41 editions. A Brassington website

records that in 1962 the company employed 16 men & closed in

1971. Photo & Info by Martyn Fretwell. Photo by courtesy

of Newark & Sherwood Museum Services.

Photo by John Elliott.

Photo by Ian Suddaby.

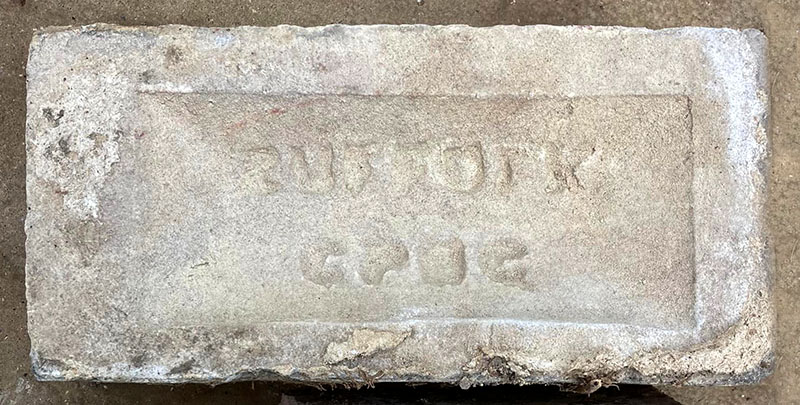

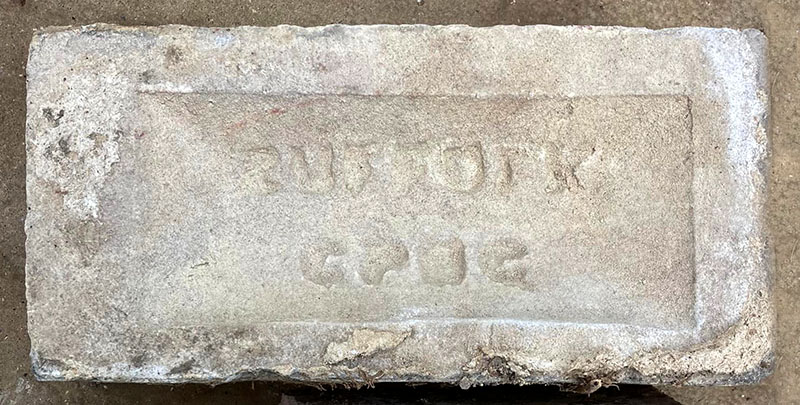

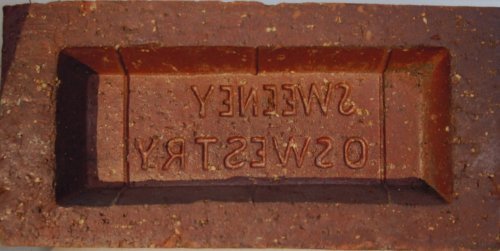

This mirror image brick was found at Brynteg, near Wrexham.

Image PRBCO.

Photo by Kirsty Crew.

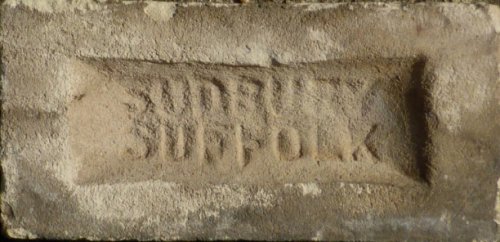

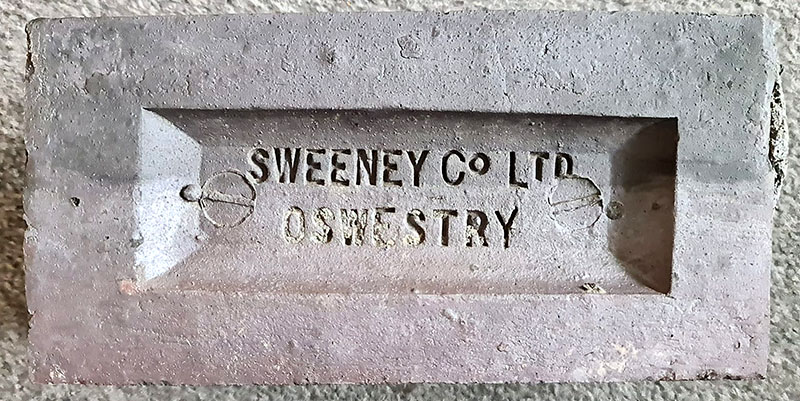

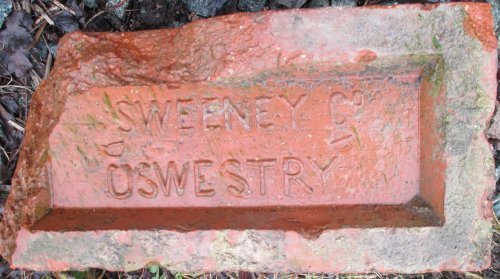

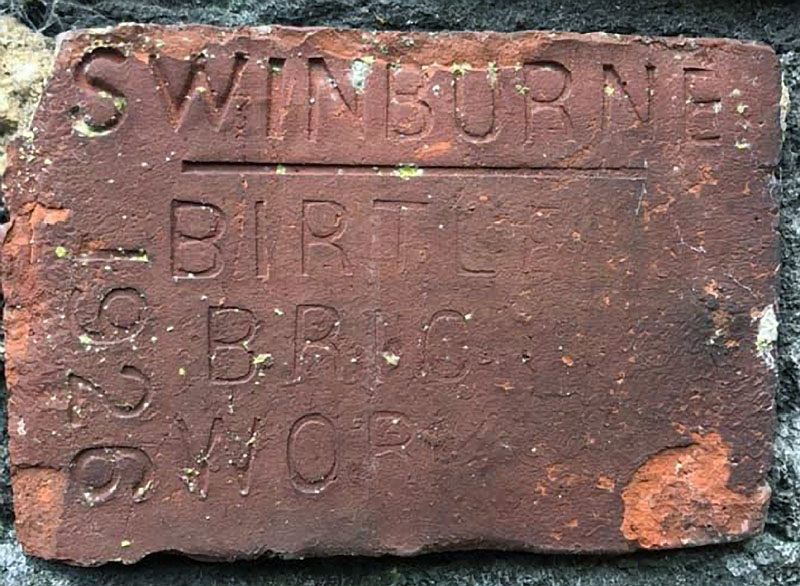

All three discovered at the Cambrian Railway Society's Weston Wharf

site Oswestry by Mike Shaw. This was where the tramway from

Sweeney's brickworks reached the main line.

Photo by Neil Ramsden.

Photo by Brian Yates.

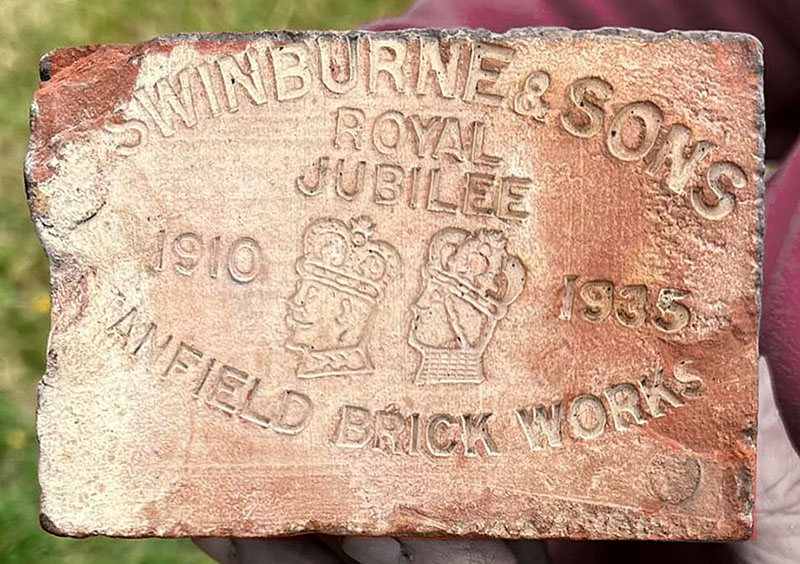

An advert in the Newcastle Courant - Friday 27 January 1888, stated that the firm was established in 1852 and could supply agricultural drain pipes, bricks and pantiles. Photo and info by Mark Cranston.

Robert Swinton is listed in Kelly’s 1876 to 1896 editions at Tattershall, Boston Lincs. Robert died in December 1899 & left his personal estate to his two sons, Edward & Christopher. Photo & Info by Martyn Fretwell.

This brick was found in Sledmere, North Yorkshire and is likely to have been made at the brickworks in Bishop Wilton, a few miles to the south west. The Sykes family of Sledmere owned the brickfield and probably employed Thomas Grant of Pocklington to manage the works throughout its life from 1854 to 1886. Photo and information from Carla van Beveren.

Sykes Macvay & Co., Castleford, W.Yorks. Slater's West Riding Directory 1887. Photo by Frank Lawson.